Five amazing eco technologies from Renault

Renault opens the doors to its innovations centre and reveals a host of new technologies and ideas for a low CO2 future

Renault is already leading the way when it comes to electric cars, but its quest to reduce emissions and make low CO2 cars more usable than ever stretches well beyond just EVs. We saw the Clio-sized EOLAB concept at the Paris Motor Show, a vision of a 2020 supermini that uses a 400kg weight reduction, plug-in hybrid powertrain and slippery aerodynamics to reduce CO2 emissions to just 22g/km.

In the more immediate future, though, Renault has a number of forward thinking solutions up its sleeve, and we were invited to explore them at its innovations centre near Paris.

1. Smaller, more efficient electric motor for the Zoe

A completely new electric motor will be fitted to the Zoe and Kangoo EV from Spring 2015. By combining the motor, junction box, power electronics and charger into a single module it has been reduced in size by 10 per cent, but more importantly it should improve the Zoe’s 130-mile range by around 10 per cent, too.

Power and torque remain constant at 87bhp and 220Nm. Other improvements include reduced charging times when using low-power supplies. We were told that a standard UK three-pin socket top-up time will be reduced by around 20 minutes.

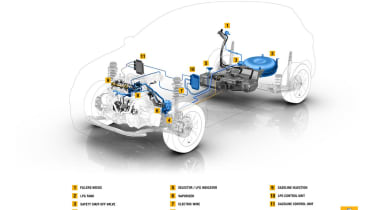

2. Dual-fuel three-cylinder petrol/LPG engine

Set to launch in the second half of 2015, the objective here was to combine the advantages of LPG (lower CO2 and running costs) with a modern petrol engine. The result is a 0.9 TCE engine that can switch seamlessly between running on LPG and petrol, without any input from the driver, but still keeps all the features that make it a modern engine – including the turbo, stop-start, energy recovery under braking and an eco-driving mode.

The result, Renault claims, is a reduction in CO2 emissions or around 10 per cent. It will be offered across Renault’s small car family that already use the 0.9 TCE engine, but only in countries such as Poland, Italy, Germany, Netherlands and France, where the LPG infrastructure is sufficient.

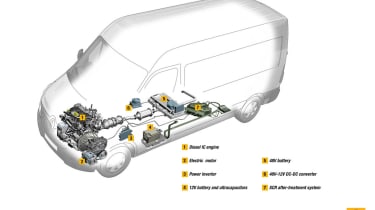

3. Mild-hybrid diesel engine for vans

The plan here is help businesses reduce their costs by cutting fuel consumption over long distances. Produced as part of the HYDIVU project (Hybrid Diesel for LCVs) project, the technology demonstrator we saw was a Renault Master van, that Renault claims has 10 per cent lower fuel consumption on long trips.

The powertrain combines an electric motor on the front axle, and a battery pack in the middle of the wheelbase, with Renault’s familiar Energy cDi 165 Twin Turbo engine up front. By adding its torque into the equation, the electric motor reduces the stress on the diesel engine as well as allowing gear ratios to be higher, which both help to cut the amount of diesel burned. Renault hasn’t given a time frame for production, but admits the technology is fully-functional.

4. Two-cylinder, two-stroke diesel engine

Renault is taking the downsizing trend to extremes with this research project – the result of which is a supercharged and turbocharged 0.73-litre two-cylinder, two-stroke diesel engine producing 67bhp and 145Nm of torque, designed for small cars in emerging markets.

The two-stroke cycle was chosen because it’s produces more power for a given capacity and has greater thermal efficiency than a four-stroke (50 per cent versus 35 per cent). Essentially a version of Renault’s familiar 1.5 dCi cut in two, the new engine promises to improve fuel consumption by as much as 15 per cent compared to its four-cylinder donor unit.

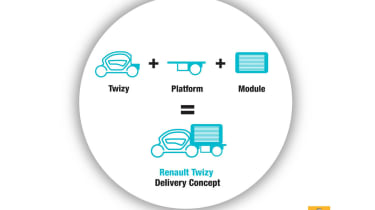

5. Twizy delivery trailer

This modified Twizy looks a bit like a minature articulated truck and is aimed at companies that are looking for a low-cost ‘final miles’ delivery solution. By removing the rear seat and creating a docking platform, the Twizy can have a detachable four-wheeled trailer hooked up with a modular container on top of that. Trials with real businesses start in April next year, after which Renault will make a decision on whether to bring it to market.

Find a car with the experts