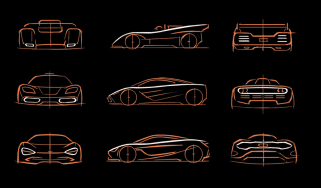

McLaren's momentum: building the Great British supercar

We meet some of the people who’ve helped McLaren become a supercar contender in next to no time

Going head-to-head with Ferrari was seen as suicide until McLaren threw down the gauntlet in 2010. In five years, the Woking company has become firmly established as a genuine rival to the Italian sports car maker.

• New McLaren 570S 2015 review

Yet it’s the acceptance of the British brand by discerning supercar customers around the world, who bought a record 1,649 models in 2014, that has underlined that McLaren has not only arrived, but is here to stay.

The firm has built a state-of-the-art factory, developed a range of successful supercars and taken on 1,200 workers in the UK. Even given McLaren’s 50-year expertise in Formula One racing, the achievement of setting up and delivering a world-class car business is unprecedented.

McLaren’s move into road cars was the sixties dream of founder Bruce McLaren, and became the vision of Ron Dennis, the mastermind behind the company’s grand prix success, who has applied the same meticulous standards of excellence and relentless pursuit of perfection.

The man responsible for turning Dennis’ vision into reality is Mike Flewitt, the chief executive of McLaren Automotive since 2012, who is pushing even harder as the firm looks to almost triple sales to 4,000 cars by 2017.

• New McLaren 675LT 2015 review

Flewitt’s own story is as spectacular as the rise of McLaren Automotive, from starting on the production lines of Ford’s Halewood plant in the eighties, as a 20-year-old fitting Escort heater hoses, to becoming the firm’s European quality director and vice president of manufacturing over 20 years later. Along the way, he gained an invaluable insight into the luxury car sector by working for Rolls-Royce/Bentley, where he set up the brand’s first ever bodyshop and became production director, before returning to Ford.

But when the chance to run McLaren came in 2012, he jumped at it. “McLaren was a rare opportunity,” he tells us. “It was the right brand at the right time, with cutting-edge technology, great engineers and good shareholders. I felt it could work.” Flewitt was also impressed by the McLaren factory and facilities at Woking: “I have worked in the car industry all over the world, but these are the most mind-blowing facilities I have seen, absolutely cutting edge.”

• McLaren to go hybrid: half the range to get electric boost by 2025

And he was equally impressed by the workforce: “Anyone working at McLaren has to have the right attitude. They also need to have dexterity because we hand-build all our cars. We even hand-paint our cars – there are no robots.” It takes 16 days to painstakingly assemble every McLaren, as Flewitt explains: “You need to be a particular kind of person to work at McLaren: passionate and motivated, someone who likes to be challenged every day. If you want an easy life, don’t come here.”

And Flewitt has a clear focus on the new models McLaren needs to reach its target of 4,000 cars by 2017, and that doesn’t include an SUV like some rivals. “An SUV doesn’t fit our brand or our engineers’ expertise. We build the best sports cars in the world – we would not build the best SUV.”

Flewitt is happy with McLaren’s model line-up, stretching from an entry price of £126,000 for the 540C up to £2million for its limited-edition ‘Ultimate’ supercars. He believes McLaren has a clear difference over rivals. “We have a motorsport background, and we use that technology to build better drivers’ cars. Our cars are extremely technology-led products that appeal to driving enthusiasts.”

He sees the firm’s futuristic headquarters and factory as a great advertisement for the business. “The factory is a big asset. It’s a physical expression of the brand, and it makes a major statement to potential customers when they arrive.”

Flewitt points to the heavy investment of the firm’s profit back into research and development as another crucial factor in McLaren’s growth, enabling it to produce a range of sports cars that showcases the technical expertise and craftsmanship of the workforce.

Flewitt also sees the buying and ownership experience of customers as critical to success of the business. “We want to keep very close to our customers and we want to have a special relationship,” he says. “Every customer is invited to the factory and given a tour.” For instance, McLaren has developed a six-event racing programme for buyers of its ultra-exclusive P1 GTR supercar, with the £1.98million price including attending the races, a bespoke colour scheme, pit garage, a coach and a technician for each owner.

But perhaps the person who best sums up what has been achieved is Amanda McLaren, the daughter of the late Bruce. A qualified nurse, Amanda was hired by the business a year ago as an ambassador and tour guide at Woking, and she clearly loves working for the firm. She says: “Dad wanted to set up a business making road cars, but it didn’t happen. But this factory and the cars have fulfilled my Dad’s dream in a way he would have been proud of.”

- • The mavericks of Morgan

- • Jaguar Land Rover’s amazing turnaround

- • Honda Swindon plant is on the up

- • Toyota marks 50 years in the UK

- • Nissan's Sunderland success story: UK car manufacturing at its best

- • Rolls-Royce: back from the dead

- • The MINI revolution: reinventing the most famous small car in the world

- • Putting the Great into Britain: exploring the car industry