Peugeot says it’s beating Porsche with game-changing battery

Integrating the charger and inverter in the battery boosts…well…everything

Less weight, more power, better efficiency and faster charging, Stellantis is moving into the final development phase of a revolutionary new battery system, testing now in a Peugeot E-3008 prototype. It’s shaping up to be in production by 2030, which would mean it’s ready for the E-3008 Mk2.

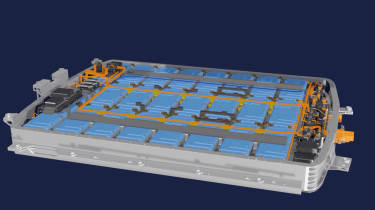

Stellantis claims the 'Intelligent Battery Integrated System' (IBIS), developed in partnership with battery specialist Saft and academics, is a game-changing technology that embeds the inverter and charger directly into the battery itself.

Electric vehicles spend a lot of time converting Alternating Current (AC) to Direct Current (DC) and back again using an inverter. For example AC from your wallbox is stored in the battery as DC, then converted back to AC to typically power electric motors. Harvesting energy from regenerative braking undergoes the same process.

Doing away with a standalone charger and inverter unlocks weight and cost benefits. A 40kg weight saving comes from fewer electronics and revised chemistry, with the knock-on effect of improved efficiency.

These ‘phase six’ development modules have been designed to fit the E-3008’s existing battery space in the STLA Medium vehicle platform. But when the engineers reach the final phase (nine) of the development cycle, the battery modules should be smaller and the next wave of Stellantis platforms designed around them instead – hopefully shaving a little height from the vehicle.

And with the elimination of the inverter and charger saving 17 litres of space on board, all these gains should boost the platform’s spaciousness and/or aerodynamics, yielding more benefits.

While Porsche has been working on a battery with similar principles, Stellantis is convinced it's ahead with its testing and affordability projections. “In terms of technical maturity, we reached Technology Readiness Level (TRL) Five and we are about to reach TRL Six,” said Anne Laliron, vice president of Stellantis technology research, in a call with Auto Express. “This is a huge maturity for such disruptive technology. We are running the first one on the road, and that's a world premiere.”

In its on-road testing, the E-3008 prototype is delivering a 10 per cent improvement in energy efficiency on the WLTC cycle (up to 15 per cent in urban driving) and a 15 per cent power bump, increasing the motor output from 150kW to 172kW (201bhp to 231bhp).

The technology also shows a 15 per cent reduction in charging time on a 7kW AC charger, cutting a full charge from seven hours to six.

Ned Curic, Stellantis' chief engineering and technology officer, emphasised the project's focus on "simplification”, stating that the innovation will help "deliver better, more affordable electric cars to our customers".

While the prototype runs Nickel Manganese Cobalt cells, Stellantis says IBIS could be rigged up with lower-cost lithium iron phosphate (LFP) chemistry. And they won’t just be limited to the STLA Medium architecture, enabling them to spread their wings to smaller vehicles.

The modules are designed to be easier to remove and not require special battery service centres, which should also cut costs and boost EV residual values. Sounds too good to be true – crack on Stellantis...

Can't wait until 2030 for a new Peugeot E-3008? Check out offers with a £6-7k saving with the Auto Express Buy A Car service!

Find a car with the experts